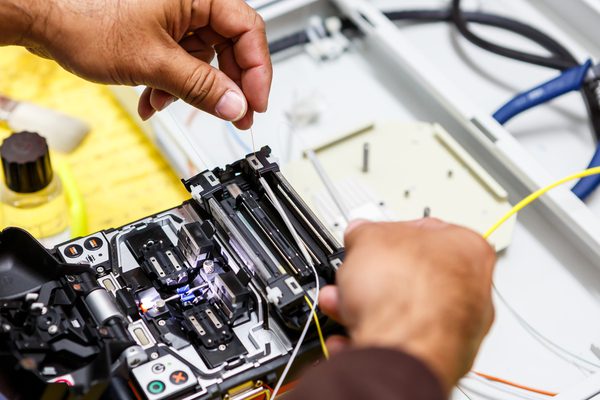

Fusion splicing has been around for several decades, and it’s a trusted method for permanently fusing together the ends of two optical fibres to achieve a specific length or to repair a broken fibre link.

As fibre deployment continues to grow, fusion splicing is crossing into the enterprise infrastructure environment and it’s more critical now than ever to understand best practices around fusion splicing.

We break down why fusion splicing is the best method, as well as highlight important stages and processes involved in fusion splicing.

We also offer some important considerations when starting the fusion splicing process to achieve the best results.

1300 130 423

1300 130 423