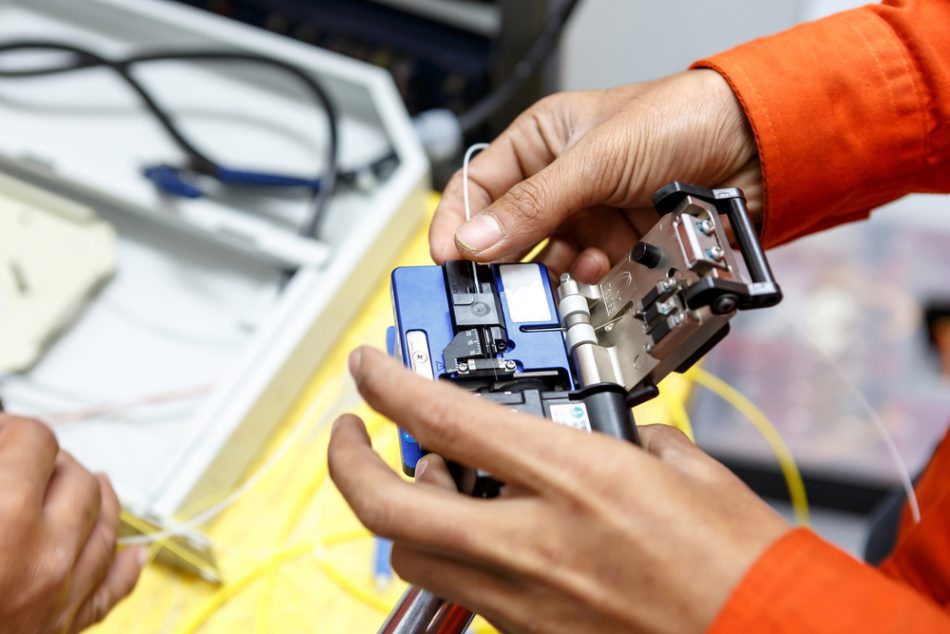

Need to extend the length of your Fibre Optic Solutions, join two fibre cables together or repair a buried cable that has been accidentally severed?

The industry leading Sumitomo Fusion Splicer is the fastest fusion splicer in the world, capable of reducing splicing and heat shrink time to 5 seconds and 9 seconds respectively.

The Sumitomo Fusion Splicer not only improves splicing performance and reliability but it has the most accurate loss estimation performance and most accurate fibre identification…

…helping ensure you can obtain an accurate, continuous and permanent connection between the fibres.

1300 130 423

1300 130 423